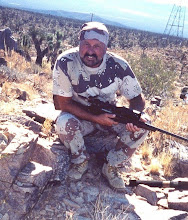

As most of you know, I like to paint my hunting rifles. I am a painting advocate for two main reasons. The most obvious is stealth. Camo painting your rifle will make it disappear in the field and prevent a barrel or receiver reflection from spooking your prey. Secondly, coating will prevent your firearm from rusting by encasing the blued steel in a jacket that seals the pores of the steel and keeps out the elements. Some may be horrified at the thought of painting a rifle but I regard my rifles as tools. Painting them not only makes them harder to be seen by predators but it also makes them much easier to maintain.

Until recently, I have been using DuPont Krylon camo spray paint with reasonably good results. It sprays on easily, dries fast and adheres pretty well to every surface. The down side is that it is not as scratch and wear resistant as I would like it to be. Therefore, I decided that I needed to investigate some other, more high-tech options.

The next step up in the durable coatings category is the “two-part” chemical process. With these coatings, you have a base product and a hardener that must be mixed in an exact ratio for success. Of the two-part coatings there is another category, baked-on and non-baked finishes. One will cure in hours by heating in an oven and the other is dry for use overnight but takes up to a month to completely cure to optimum hardness.

I don’t know about you guys but if I attempted to bake a painted gun part in our kitchen oven, my wife would not be too pleased. Keep in mind that while baking, certain chemicals flash off and permeate your oven (and house) while the baking/curing process is in progress. I just don’t think that would fly at our house. So, I began to look more closely at the non-bake type finishes.

Upon further investigation, one name stood tall above the rest. The name of the product is DuraCoat. Steve Lauer of Lauer Weaponry is the inventor of DuraCoat and the development of this firearm-specific coating process has changed everything. DuraCoat is now recognized as “the” premier firearm coating and Lauer’s satisfied customers now span the globe.

Like many other inventors you’ve read about, Steve Lauer developed his DuraCoat process in a residential garage. After years of trial and error, Steve finally developed a product that displayed all of the characteristics he was looking for. DuraCoat was born.

DuraCoat is a two-part mix that must be applied by spraying with an airbrush or HVLP spray setup. DuraCoat can not be brushed on to a surface. The surface must be clean and should be roughed up enough to provide some “tooth” for the coating. Once applied, it adheres to the surface like a tight plastic wrap. It sprays on thin and really holds on when cured. After spraying your rifle, it dries to the touch in 30-minutes to an hour and your firearm is ready for service in 24-hours. Complete curing will take several weeks. How durable is DuraCoat? Steve Lauer says that under normal use, DuraCoat will last several lifetimes. That seems like a reasonable service life to me.

One of the other benefits of DuraCoat is the almost endless choice of colors. With almost 100 different shades and finishes, you will surely find one (or several) that will suit your needs. If you plan on a camo job, Lauer also sells camo template kits that will pimp out your hunting rifle like you never thought possible. The Lauer Weaponry website Lauer Weaponry has a world of info concerning the DuraCoat product, color illustrations and various camo designs and kits.

DuraCoat is a process that is relatively easy to apply, especially if you purchase one of the many kits that are offered by Lauer Weaponry and follow the instructions. The kits also include a CD that can be loaded into your computer so the process can be watched. Lauer has made the tricking out of your favorite hunting arm as easy as possible and the customer service is second to none. Stave Lauer wants you to succeed and he and his staff are there for you should you have any questions or problems. When I called for information, Steve talked with me for at least 15-minutes and was very informative.

I recently purchased a curio & relic Enfield rifle that was produced in 1965. The finish on the rifle was failing and the stock was pretty grimy. After taking the entire rifle apart, I decided to refinish the metalwork with DuraCoat. I purchased a basic kit from Lauer Weaponry and got busy.

My .308 caliber Enfield was manufactured in India at the Ishapore Armory and as a normal practice; they coat the metal on their rifles with some kind of funky black paint. I think by the look of it, they used a dirty cotton ball to apply the paint. Needless to say, that had to go. The first step was the removal of mass quantities of Cosmoline (a light amber ointment to seal the rifle’s pores and prevent rust from forming). Once that mess was removed from the stock and metal parts, the stripping of the funky black paint began. After stripping off layers of the black paint, the metal was cleaned, all rough edges were faired with a file and the metal surface was sanded with 220-grit sandpaper. Then, it was on to every screw. All of the screws had idiot marks (apparently they only have one size of screwdriver in India, (the wrong size) and after careful filing and sanding, they were all returned to like new condition and prepped for the DuraCoat finish.

After all of the prep work was done, I laid everything out for spraying with DuraCoat and began the process. For the Enfield, I chose the “Parker” color. I have never used an airbrush before but it was easy to learn and the DuraCoat process went off without a hitch. Apply the product as suggested in the instructions, in thin coats, and you will have no problems. I started with the barrel and receiver and then shot light coats on everything. I did about four rounds of light coats before I was satisfied with the finish. It dried to the touch in about 30-minutes but I let all the parts sit for 24-hours before messing with them. No kidding, this stuff is fool-proof. I am convinced that anybody can use this stuff and if the directions are followed, the results will be perfect the first time.

The Enfield’s Mahogany furniture has been stripped, cleaned, and sanded. It’s now undergoing a hand rubbed, tung oil finish and that will take a lot more time and effort than the DuraCoat process. After seeing the completed DuraCoat finish and the progress on the stock, I am confident that when this rifle is re-assembled, it will be one super-sweet example of the .308 caliber Ishapore Enfield.

What can I say? I am sold on the merits of DuraCoat and I can think of several other rifles in my safe that will benefit from a DuraCoat finish. It’s fun, easy, affordable and a great way to preserve your favorite hunting or defense arms. For more examples of the DuraCoat finish, see "Red's Page" on the http://www.redhunterllc.com website.

Friday, August 28, 2009

Subscribe to:

Post Comments (Atom)

REALLY nice looking Enfield!

ReplyDeleteHow can i supply material of the duracoat-dupont krylon to coating? Can i buy it?

ReplyDelete